Building the Box Joint Jig ~ Page 2 |

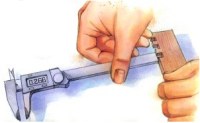

Step 2. Adjust your dado set for a cut that's .001" wider than the joint fingers (.251" in our example). With stackable dado sets you can place commercially made shims between the cutters, or make your own shims from various papers (standard tablet paper measures .002-.005" thick, some tissue and waxed papers measure .001" thick). Check your adjustment by measure a test cut with your calipers as shown below. Raise the dado set 1/2" above the tabletop. Step 2. Adjust your dado set for a cut that's .001" wider than the joint fingers (.251" in our example). With stackable dado sets you can place commercially made shims between the cutters, or make your own shims from various papers (standard tablet paper measures .002-.005" thick, some tissue and waxed papers measure .001" thick). Check your adjustment by measure a test cut with your calipers as shown below. Raise the dado set 1/2" above the tabletop. |

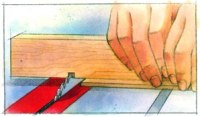

Step 3. Cut the notch that holds the pin in part A. Do this by holding part A against the miter gauge with part B beneath it as shown below. Do not cut into part B. Step 3. Cut the notch that holds the pin in part A. Do this by holding part A against the miter gauge with part B beneath it as shown below. Do not cut into part B. |

Step 4. Cut a 1/4 x 1/4 x 6" strip of hardwood that fits snugly into the notch you just cut in part A. (The strip should slip into place, yet fit tightly enough so it doesn't fall out.) Cut a 1-1/2" pin from the strip and glue it into the notch, flush with the back of part A. Save the leftover strip. Screw part B to part A. Step 4. Cut a 1/4 x 1/4 x 6" strip of hardwood that fits snugly into the notch you just cut in part A. (The strip should slip into place, yet fit tightly enough so it doesn't fall out.) Cut a 1-1/2" pin from the strip and glue it into the notch, flush with the back of part A. Save the leftover strip. Screw part B to part A. |

| Step 5. Set your miter gauge for a 90° cut. Use the leftover strip to position the jig assembly on the miter gauge. Do this by aligning the jig pin 1/4" from the path of the dado set as shown above. With the pin aligned, temporarily clamp the jig to the miter gauge, then affix the gauge to the jig with screws. Replace the miter gauge into its slot and cut through parts A and B. Attach the blade guard (C) centered behind the notch you just cut. During this and the following steps, apply pressure to the miter gauge to hold its bar firmly against the right side of the slot. This will keep its distance from the dado set consistent during cuts. |

Step 6. Position a piece of scrap stock as shown above, and cut a notch into the scrap piece. Position this notch over the pin and make another cut. Position that notch over the pin and repeat the cut. With your calipers, check the width of the fingers. They should be .001" under your desired finger width. (For our 1/4" fingers the calipers should read .249".) Step 6. Position a piece of scrap stock as shown above, and cut a notch into the scrap piece. Position this notch over the pin and make another cut. Position that notch over the pin and repeat the cut. With your calipers, check the width of the fingers. They should be .001" under your desired finger width. (For our 1/4" fingers the calipers should read .249".) |

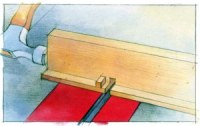

Step 7. Chances are your jig will need some adjustment to achieve the necessary finger width. If the fingers are too wide, say .255" in our example, tap the end of the jig closest to the blade with a hammer as shown above. Make more test cuts and tapping adjustments as necessary. If the fingers are too narrow (.245" in our example), tap the other end of the jig. Even though the jig is screwed in place, the hammer taps will make these fine adjustments. Step 7. Chances are your jig will need some adjustment to achieve the necessary finger width. If the fingers are too wide, say .255" in our example, tap the end of the jig closest to the blade with a hammer as shown above. Make more test cuts and tapping adjustments as necessary. If the fingers are too narrow (.245" in our example), tap the other end of the jig. Even though the jig is screwed in place, the hammer taps will make these fine adjustments. |

Step 8. With your calipers, check the depth of the fingers in your scrap stock. Adjust the height of your blade until the depth reads .016" more than the width of your fingers (.266" in our example). This leaves the fingers long enough so you can sand them flush with the box later. Step 8. With your calipers, check the depth of the fingers in your scrap stock. Adjust the height of your blade until the depth reads .016" more than the width of your fingers (.266" in our example). This leaves the fingers long enough so you can sand them flush with the box later.

Next Page: Making Box Joints ... |

🌵 Search azWoodman

As a participant in the WOOD Store Affiliate Program, we earn commissions on sales generated by advertising and linking to WOODStore.net.

As a participant in the WOOD Store Affiliate Program, we earn commissions on sales generated by advertising and linking to WOODStore.net.